Locking pins by KIPP

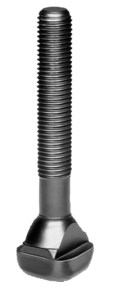

A locking pin is a pin that is used to join or lock two or more parts. They offer a simple and effective way of connecting components without the need for tools such as spanners or screwdrivers. Locking pins are used in areas where quick assembly or disassembly of components is required. They are made up of a cylindrical pin with a head at one end and a structural connection at the other. The structural connection can be a thread, a slot or a pin hole, for example.

Locking pins can be used in many ways and ranges from simple applications to complex mechanical systems. Some of the most common applications and uses of locking pins are:

- Assembly and disassembly of assemblies: Locking pins allow for quick and simple assembly as well as disassembly of assemblies. They can be used to temporarily fasten or permanently connect parts.

- Safety precautions: These pins are used in many machines and devices to secure moving parts and prevent accidents. For locking doors, hatches or covers, for example.

- Adjustment and alignment: Locking pins can be used to adjust and align parts before they are finally attached. This is particularly useful when assembling precision mechanical systems.

- Support structures: In structures such as scaffolding and shelving systems pins are used for connecting and stabilizing of support structures.

- Quick-change devices: In industrial applications, such as manufacturing, pins can be used in quick-change devices, to change tools or components quickly.

Simple and quick fastening using locking pins

Different types of operating parts

Maintenance and care of locking pins

KIPP as an experienced manufacturer of locking pins

Simple and quick fastening using locking pins

The versatility of locking pins makes them important elements in various industries and applications. In the automotive industry they are used for a wide range of applications. These include attachment of body parts, engine and transmission components, wheel suspensions and brake systems. The pins allow for quick assembly in production lines and facilitate repairs and maintenance work.

In aerospace assemblies must be able to withstand extreme loads and still be easy to assemble and maintain. Here locking pins are used to fasten structural components, panelling, landing flaps and other systems.

In the mechanical engineering sector, locking pins are used for the assembly of plants, gearboxes, conveyor belts and other machine components. They allow for flexible design and quick changes or adjustments in the production process.

Locking pins are used in the construction industry for temporary and permanent structures, such as scaffolding, support structures, roof structures and railings. They offer a simple and secure method of connecting and fastening components.

In all these industries, pins play a key role in the construction, assembly and maintenance of machines, plants and structures. Their versatility and reliability make them an essential fastening element in modern industry.

There are several key factors to be considered when selecting the right products for specific requirements. Firstly, it is important to know the exact dimensions of the components to be connected in order to ensure correct pin size. Length and diameter of the locking pin has to be suitable to ensure a secure and stable connection.

The material the pin is made of is another important aspect. Depending on the requirements of the application, products can be made of different materials such as steel and stainless steel. For locking pins with grip option, grips are made of thermoplastic. The choice of material depends on factors such as the strength needed, operating environment and corrosion resistance.

Different types of operating parts

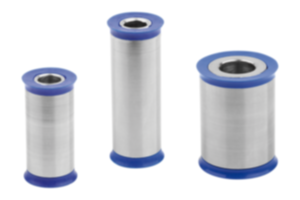

The KIPP product range includes five different types of operating parts. These not only differ in thread size, length and material (steel and stainless steel), but also in style.

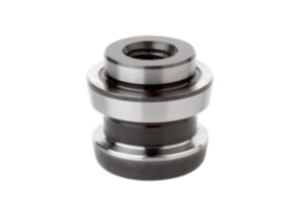

Locking pins with magnetic axial lock

Locking pins with magnetic axial lock are an efficient solution for quick and easy fastening of parts. An magnet integrated into the grip ensures reliable axial positioning, which holds the stainless steel locking pin in the insertion position. The smooth surface and vertically arranged plug-in hole help to improve holding force and as a result ensure a secure connection. |

With these properties, the locking pins with magnetic axial locking offer a reliable and versatile solution for different applications in industry and trade.

Locking pins with magnetic axial locking are available with a pin diameter of 6 mm, 8 mm, 10 mm und 12 mm. The bolt length ranges from 15 mm to 80 mm.

The handle of the bolt with axial lock is made of thermoplastic, while the steel parts are made of stainless steel. 1.4305.

For a detailed description of the materials see our material overview. This will provide you with all you need to know about the materials.

Locking pins with plastic mushroom grip

Locking pins with plastic grip are particularly suitable for applications where smooth operation and a good grip are required. The plastic mushroom handle offers pleasant haptics and ensures safe handling, even in wet or oily conditions. While the mushroom handle is made of plastic, the bolt is made of stainless steel.

For certain measurements you are able to select the length of the stainless steel bolt from 17 mm to 60 mm. The mushroom grip is available with a diameter of 25 mm or 33 mm, while the bolt diameter is 6 mm, 8 mm, 10 mm und 12 mm.

Locking pins with stainless steel key ring

Locking pins but unloseable? That poses no problem for us!

Our steel bolts feature a stainless steel key ring and are therefore very easy to secure. Unloseable locking pins are available with a pin diameter of 6 mm and 8 mm. The bolt length can be selected in increments between 22 mm and 58 mm. While the pin is made of steel, the key ring is made of stainless steel. In order to remain flexible when using operating parts, we recommend that to use a retaining cable or ball chain. This ensures that the locking pin always stays where it belongs.

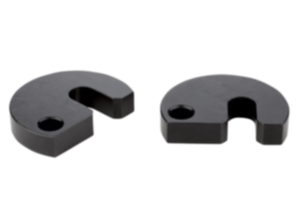

Locking pins with folding latch

In case of locking pins with folding latch the wide folding latch enables a large cross-section of the parts to be connected to be secured. The locking pin is able to withstand axial loads and also suitable for the permanent connecting of moving parts. The locking slots in the folding latch allow the safety catch to be precisely positioned. You can select either "closed" and "open". The locking pin with folding latch is made of steel and available with pin lengths (L5) of 31 mm, 46 mm and 56 mm. In the closed position B (folding latch in closed position) is 16.9 mm, in the open position (B1) 2 mm. (see illustration) |

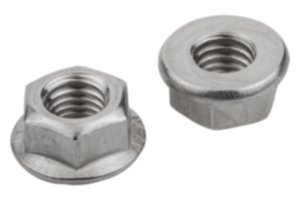

Locking pins with axial lock

Locking pins with axial lock are an extremely practical fastening solution for a wide range of applications. These special locking pins feature an integrated locking device that ensures axial position locking. This ensures that the locking pin is held in the desired insertion position and cannot fall out unintentionally. Locking pins with axial lock are used in numerous areas where reliable and repeatable positioning of components is necessary. Due to their ease of use, reliability and versatility, locking pins with axial locks are a practical solution.

The KIPP product range offers pins with a diameter of 6 mm, 8 mm, 10 mm and 12 mm. The bolt length can be selected between 16 mm and 38 mm. When installing the operating parts, the dimension X (1.1 mm or 1.2 mm) in the counterpart should be noted as an insertion aid. The chamfer for the counterpart X should be min. x 45°.

Maintenance and care of locking pins

Care and maintenance of operating parts is crucial to prolong service life and maintain performance. Here are 4 important tips for you.

- Carry out regular inspections of the pins to detect signs of wear, damage or looseness. In particular, check threads, head structures and locking devices for wear or damage.

- Keep the pin clean by regularly removing dirt, dust and other deposits. To clean use a brush, compressed air or a cloth. Make sure you also clean the threads and bores thoroughly.

- For bolts with a thread or locking mechanism, appropriate lubrication can reduce friction and extend the service life of the bolt. Use lubricants that are suitable for the application and the ambient conditions.

- If locking pins are damaged, badly worn or no longer functional, replace them immediately. Do not use pins that show signs of cracks, deformation or other defects, as this may affect safety and performance.

By following these care and maintenance tips, you may extend the service life of your products and ensure that they work perfectly.

KIPP as an experienced manufacturer of locking pins

High-quality socket pins by KIPP offer a number of advantages in terms of safety, reliability and durability. Careful selection and proper use can maximise the benefits.

The bolts offer high strength and load rating, resulting in improved safety and reliability. They can withstand high loads and provide a more stable connection between components, which reduces the risk of accidents and failures. The use of high-quality materials and manufacturing processes increases durability of the locking pins. This reduces the need for frequent replacement or maintenance work, saving time and money.

By investing in high-quality locking pins, you will be able increase efficiency and reduce operating costs while ensuring safety and reliability of your systems. Customers particularly benefit from our wide range of locking pin in various sizes, materials and styles.