Screw plugs / press-in plugs

Press-in plugs and screw plugs

A press-in plug is a component that is used to close openings or cavities in various technical systems, machines or appliances. These small but important elements are used to prevent the ingress of dust, dirt, moisture or other unwanted substances that could affect the proper function or performance of a system. The press-in plug protects the product from external influences.

Press-in plugs are available in various shapes and sizes to meet the differing requirements of different applications. They are inserted into the opening or bore to ensure a secure seal

The use of press-in plugs is widespread in various industries, from electronics and the automotive industry to household appliances and food processing machines.

In contrast, screw plugs seal threaded openings and make a decisive contribution to the functional reliability of systems In contrast to conventional screws, which are often used for joining or fastening, the main function of a screw plug is to seal an opening and protect from external influences or keep fluids inside.

Screw plugs come in various shapes, sizes and materials and are designed to provide a tight seal. They are screwed into threaded openings and are used to keep out dust, dirt, moisture or other undesirable substances, or prevent internal fluids from leaking out.

This type of screw is used in numerous industries, including electronics, automotive, aerospace and machine construction. The choice of screw plug depends on the specific requirements of the application.

Versatile applications of sealing elements

Overview of the various sealing components from KIPP

Installation of sealing elements in technology

Press-in plugs und screw plugs from KIPP

Versatile applications of sealing elements

The application of sealing elements such as press-in plugs or screw plugs lies in their ability to seal and secure openings or cavities in technical systems, machines or appliances. This extends across a wide range of sectors, from the construction industry to medical technology. These items serve to ensure the proper functioning, , and durability of systems by protecting them from undesirable influences.

In electronics, for example, sealing elements are used to protect unused ports and openings from dust, moisture and other environmental influences. This helps to extend the service life of electronic components. In the automotive industry, sealing elements safeguard sensitive mechanisms. Cables and pipes are also protected from external influences, which improves the reliability and safety of the vehicles.

The aerospace industry uses sealing elements to protect critical systems from extreme climatic and cosmic conditions. In the food industry, they are used to protect production facilities from contamination and to comply with hygiene standards. Sealing elements are used in machine construction to protect machines from dust and dirt and thus ensure efficient performance.

Overview of the various sealing components from KIPP

KIPP offers a wide range of sealing elements that all meet the highest quality standards. Be it press-in plugs or screw plugs - our products are characterised by precision and reliability.

Our screw plugs are available with various thread sizes and meet the strict DIN standards. Press-in plugs and screw plugs manufactured according to DIN meet the specific requirements and standards of the German Institute for Standardisation. DIN standards define precise technical specifications and requirements to ensure the quality, safety and the interoperability of products. This means that the sealing elements have been manufactured in accordance with the specified DIN standards. This in turn ensures uniform quality and interoperability.

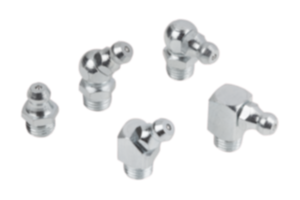

The following DIN standard screw plugs are available:

- Screw plugs with hex socket and tapered DIN 906 threads are ideal for sealing bores with a parallel internal thread.

- The DIN 908 screws with collar and hex socket are made from steel and screwed in using a hex key. The diameter of the collar on these screw plugs is available in diameters 12 mm - 55 mm.

- DIN 910 hex head screw plugs with collar are made of steel and are screwed in using a spanner.

In addition to the screw plugs mentioned above, the KIPP range also includes other types:

- Different screw plug types

The screw plugs are available in diverse versions.

- With or without collar, with fill symbol or drain symbol,

- with hex socket,

- with hex head,

- with magnet,

- with dipstick.

They are available in different styles.

Form A – without vent

Form B – with vent

Form C – with vent and air filter

are made from 1.0737 steel. They have a rubber O-ring. These screw plugs can be used at an operating temperature of - 20 °C to 100 °C.

have a flat seal. Unlike the plastic screw plugs which are marked OIL, DRAIN or FILL, aluminium screw plugs have no markings on top.

Magnetic aluminium screw plugs are also available. The magnet attracts iron particles in oil.

KIPP has these press-in plugs in its range:

- Press-in plugs made from polyamide 66 are available in three styles.

Form A – without vent

Form B – with vent

Form C – with vent and air filter

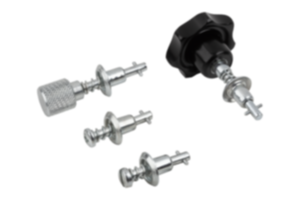

The housing and cap of these are made from polyamide 66. The plugs with dipstick are also available in three styles.

Form A – without vent

Form B – with vent

Form C – with vent and air filter

Installation of sealing elements in technology

The installation of sealing elements, such as press-in plugs and screw plugs, requires a careful and precise approach. Firstly, it is important to ensure that the items have been correctly selected to meet the specific requirements of each application.

The actual installation begins by cleaning the plug thoroughly and carefully positioning it over the threaded opening or bore to be sealed. Screw plugs should be carefully screwed in by hand, ensuring the threads are not crossed.

During installation, it must be ensured that the element is inserted evenly and without excessive pressure in order to prevent damage to the threads. Some sealing elements are equipped with some type of seal to ensure that the seal is effective. In such cases, it is important to ensure that the seal ring is positioned correctly to guarantee an optimum seal.

Once the sealing element is correctly positioned and screwed in by hand, it is tightened using a spanner or key. Ensure that the tightening torque recommended by the manufacturer is adhered to in order to guarantee a secure seal without damaging the thread.

Press-in plugs und screw plugs from KIPP

Quality, precision and reliability are our top priorities. Our press-in plugs and screw plugs are not just simple components - they are the optimum protection for your systems.

We rely on materials of the highest quality and state-of-the-art production technologies. As a result, we not only guarantee compliance with strict quality standards, but also a long service life for our products. Our press-in plugs and screw plugs meet the strict DIN requirements. These standards not only guarantee high product quality, but also compatibility and safety.

Our team at KIPP is always available to answer your questions or help you choose the ideal sealing solution.